Australasian firms Li-S Energy and Kea Aerospace have signed a collaboration agreement to test lithium-sulphur batteries in unmanned aircraft applications.

The deal will see Australian firm Li-S’ battery technology power New Zealand firm Kea Aerospace’s (Kea) high altitude un-crewed aerial vehicles (UAVs).

The companies will incorporate Li-S’ battery cells and BMS technology into a Kea battery pack design, with the aim of starting ground testing later this year.

Kea plans to use lithium-sulphur technology in its ATMOS Mk2 UAV, which will be capable of continuous flight for several months. The aircraft’s motors will use the battery at night and solar cells during the day (with excess solar power used to recharge the battery).

Lithium-sulphur’s lighter weight (than lithium-ion) and high energy density is a perfect fit for unmanned aircraft applications targeting multi-month flight times. Although, the technology has historically suffered from low cyclability.

Dr Lee Finniear, Li-S’ CEO, said his company’s initial focus on the drone, defence and electric aviation markets was producing ‘incredible opportunities’ for lithium-sulphur technology.

The stratospheric UAV market is a key sector of interest with enormous commercial potential, added Finnier.

Li-S technology

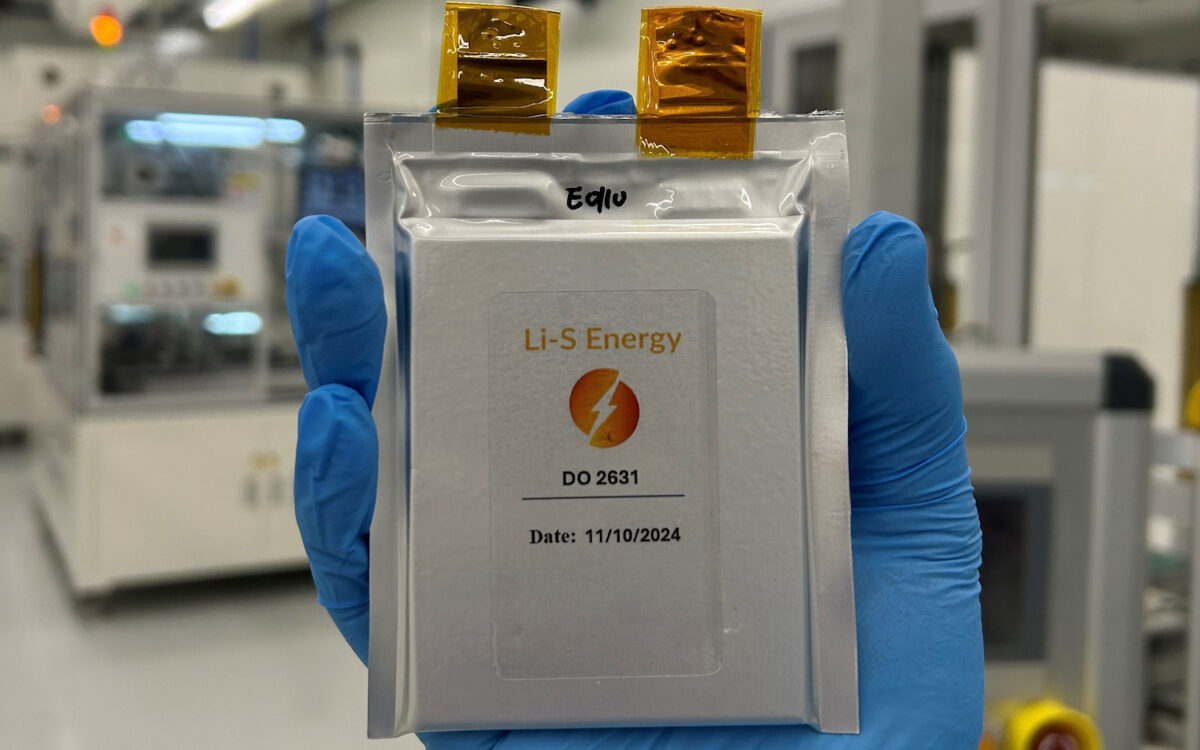

Last August, Li-S opened its state-of-the-art lithium-sulphur pouch cell production facility in Victoria, Australia. When completed, the plant is planned to have 200MWh of production output.

The AUS$10 million ($6.3 million) facility spans the entire production process from creating and coating cathode powders to final cell fabrication and testing.

The company has said its GEN3 cells demonstrate a gravimetric energy density of more than 400Wh/kg, and a volumetric energy density of 540Wh/l in laboratory tests.

The 20-layer cells use Li-S’ patent protected Li-nanomesh technology, and incorporates Boron Nitride Nanotubes (BNNTs) into the cell construction to reduce dendrite growth to improve safety and cycle life.

The company has successfully completed a series of nail penetration tests on its multi-layer 2.5Ah lithium-sulphur cells, which were built on its Phase 2 micro-production line at Geelong, Victoria. Test conditions were applied with cells at 0%, 20%, 40%, 60%, 80% and 100% state of charge and at beginning of life, middle of life and end of life cell ages.